1

/

of

2

masuyume

TMC Vise II

TMC Vise II

Regular price

$425.00 USD

Regular price

Sale price

$425.00 USD

Unit price

/

per

Shipping calculated at checkout.

Out of stock

Couldn't load pickup availability

The pinnacle of tying vises bearing the TMC name, with everything considered from the fly tyer's point of view

.

The TMC is the ultimate tying vice, designed from the fly tyer's point of view, and is the ultimate in fly tying vises.

The TMC is the most advanced tying vice in the TMC lineup, with a shaft that is designed from a tyer's point of view, allowing for a high degree of freedom in all positions to produce well-balanced, highly accurate flies.

The distance from the jaw to the hand position on the top of the shaft is also carefully designed, and the size and position of each part is also determined with ergonomics in mind.

The solid rigidity that allows you to concentrate on your tying, the beauty of the finish of each and every part that has been created with high precision, and above all, the high level of basic performance as a tying vice that has been polished without compromise, will give you the pleasure of using it.

Most of the tools and tools in the world can be divided into "necessary" and "convenient" concepts, and the TMC Vice II is more in the "convenient" category. However, the more you use TMC Vise II, the more it becomes a "necessity".

Compatible with hook sizes from #8/0 to #32.

Eye contact

The quickest way to tie an accurate fly is to look at it with your "eyes". There are many steps to look at while tying, such as dividing the wing evenly, looking at the symmetry of the fly, and looking at the angle at which the thread is wound. Ensuring that each of these steps is done correctly will result in a fly that is accurately balanced. The TMC Vise II allows you to look at the fly from all angles in the same position, which increases the accuracy of the fly. When looking at the fly, it is important to look at the fly from the front. The TMC Vice II is a shortcut to winding a well balanced fly, and it also promises comfortable fishing with an accurately wound fly.

Cut Work

In tying, the angle at which the scissors are inserted is 3D, but there are limitations to how human joints can bend. Also, the tying environment varies depending on the height of the desk and the height of the chair. Even in sometimes inconvenient situations, the multiple joints of the TMC Vise II move freely, allowing for effortless cutting work in the same position without having to rearrange the hooks. The TMC Vise II also allows for cutting from the tail side, which is difficult with conventional vices.

There is no need to change the position of the hooks when cutting.

Height Control

The center shaft can be extended and retracted to allow you to tie at your preferred height.

This is surprisingly useful since the height of tables and chairs varies depending on the tying environment. Use it at your preferred height.

There is no need to worry about the height of the center shaft.

Tying Position

You can choose various tying positions.

A.

The typical tying position is the Renzetti position, which rotates around the A shank.

The disadvantage of this position is that it is difficult to attach tails, etc. However, TMC Vice II can easily raise the head as shown in the figure to the upper side, which ensures comfortable work. The TMC Vise II can be easily returned to its original position, so it can be used as needed.

When rotated to the back, the fly can be viewed from directly below.

BThis is the most common tying position for general vises.

B

B This is the most common tying position for the common vise, and is recommended for those familiar with this position.

Both positions have their own unique uses, and if you can use both positions, your tying world will expand.

As for how the fly rotates, please experiment to find the best position for you.

There is a lot to be said for the best position for your fly.

There are many ways to use the fly.

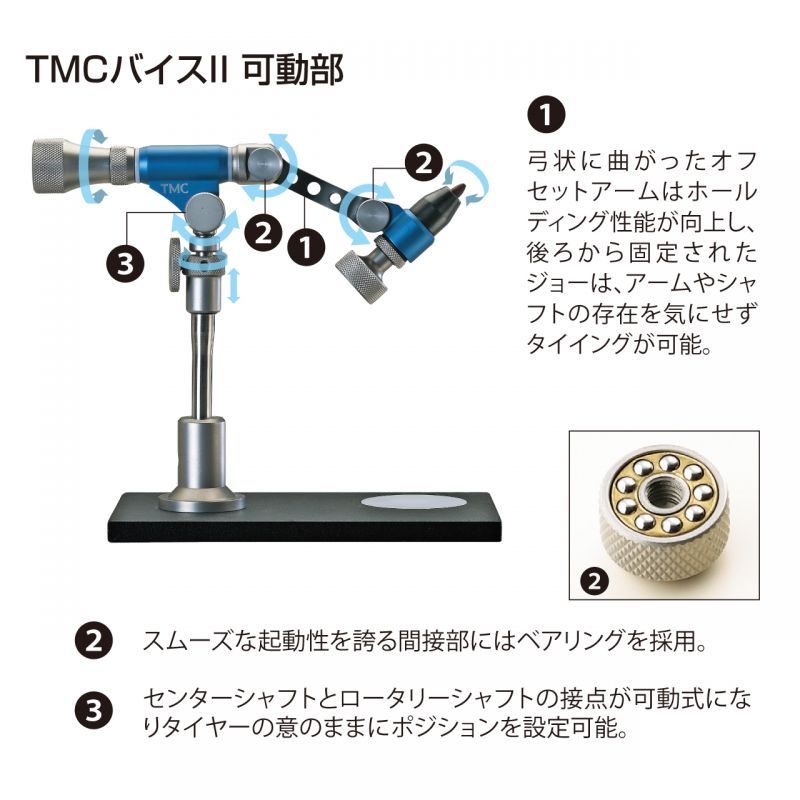

Numerous joints to cover all angles and a bearing mechanism to make the movement smooth

1Bowed offset arms improve holding performance, and jaws fixed from behind allow tying without worrying about the presence of arms or shafts.

2Bearings are used in the indirects for smooth starting performance.

2 3The contact point between the center shaft and rotary shaft is movable, allowing the tyer to set the position at will.

.

The TMC is the ultimate tying vice, designed from the fly tyer's point of view, and is the ultimate in fly tying vises.

The TMC is the most advanced tying vice in the TMC lineup, with a shaft that is designed from a tyer's point of view, allowing for a high degree of freedom in all positions to produce well-balanced, highly accurate flies.

The distance from the jaw to the hand position on the top of the shaft is also carefully designed, and the size and position of each part is also determined with ergonomics in mind.

The solid rigidity that allows you to concentrate on your tying, the beauty of the finish of each and every part that has been created with high precision, and above all, the high level of basic performance as a tying vice that has been polished without compromise, will give you the pleasure of using it.

Most of the tools and tools in the world can be divided into "necessary" and "convenient" concepts, and the TMC Vice II is more in the "convenient" category. However, the more you use TMC Vise II, the more it becomes a "necessity".

Compatible with hook sizes from #8/0 to #32.

Eye contact

The quickest way to tie an accurate fly is to look at it with your "eyes". There are many steps to look at while tying, such as dividing the wing evenly, looking at the symmetry of the fly, and looking at the angle at which the thread is wound. Ensuring that each of these steps is done correctly will result in a fly that is accurately balanced. The TMC Vise II allows you to look at the fly from all angles in the same position, which increases the accuracy of the fly. When looking at the fly, it is important to look at the fly from the front. The TMC Vice II is a shortcut to winding a well balanced fly, and it also promises comfortable fishing with an accurately wound fly.

Cut Work

In tying, the angle at which the scissors are inserted is 3D, but there are limitations to how human joints can bend. Also, the tying environment varies depending on the height of the desk and the height of the chair. Even in sometimes inconvenient situations, the multiple joints of the TMC Vise II move freely, allowing for effortless cutting work in the same position without having to rearrange the hooks. The TMC Vise II also allows for cutting from the tail side, which is difficult with conventional vices.

There is no need to change the position of the hooks when cutting.

Height Control

The center shaft can be extended and retracted to allow you to tie at your preferred height.

This is surprisingly useful since the height of tables and chairs varies depending on the tying environment. Use it at your preferred height.

There is no need to worry about the height of the center shaft.

Tying Position

You can choose various tying positions.

A.

The typical tying position is the Renzetti position, which rotates around the A shank.

The disadvantage of this position is that it is difficult to attach tails, etc. However, TMC Vice II can easily raise the head as shown in the figure to the upper side, which ensures comfortable work. The TMC Vise II can be easily returned to its original position, so it can be used as needed.

When rotated to the back, the fly can be viewed from directly below.

BThis is the most common tying position for general vises.

B

B This is the most common tying position for the common vise, and is recommended for those familiar with this position.

Both positions have their own unique uses, and if you can use both positions, your tying world will expand.

As for how the fly rotates, please experiment to find the best position for you.

There is a lot to be said for the best position for your fly.

There are many ways to use the fly.

Numerous joints to cover all angles and a bearing mechanism to make the movement smooth

1Bowed offset arms improve holding performance, and jaws fixed from behind allow tying without worrying about the presence of arms or shafts.

2Bearings are used in the indirects for smooth starting performance.

2 3The contact point between the center shaft and rotary shaft is movable, allowing the tyer to set the position at will.

Shipping Schedule

Shipping Schedule

After order confirmation, in-stock items will be shipped on the same day if payment is completed by 5:00 p.m.

Orders placed after 5:00 p.m. will be shipped the following day.

If we need to confirm inventory separately, we will contact you by e-mail.

Shipping charges

Shipping charges

Shipping fees vary depending on the product and delivery area.

Please check the shipping fee displayed on the payment screen.

Shipping Method

Shipping Method

Domestic: Yamato Transport

Overseas: FedEx

Please note that you cannot set a preferred delivery date and time.

Business Hours

Business Hours

Open all year round (9:00~20:00)

Share